Designed by Freepik

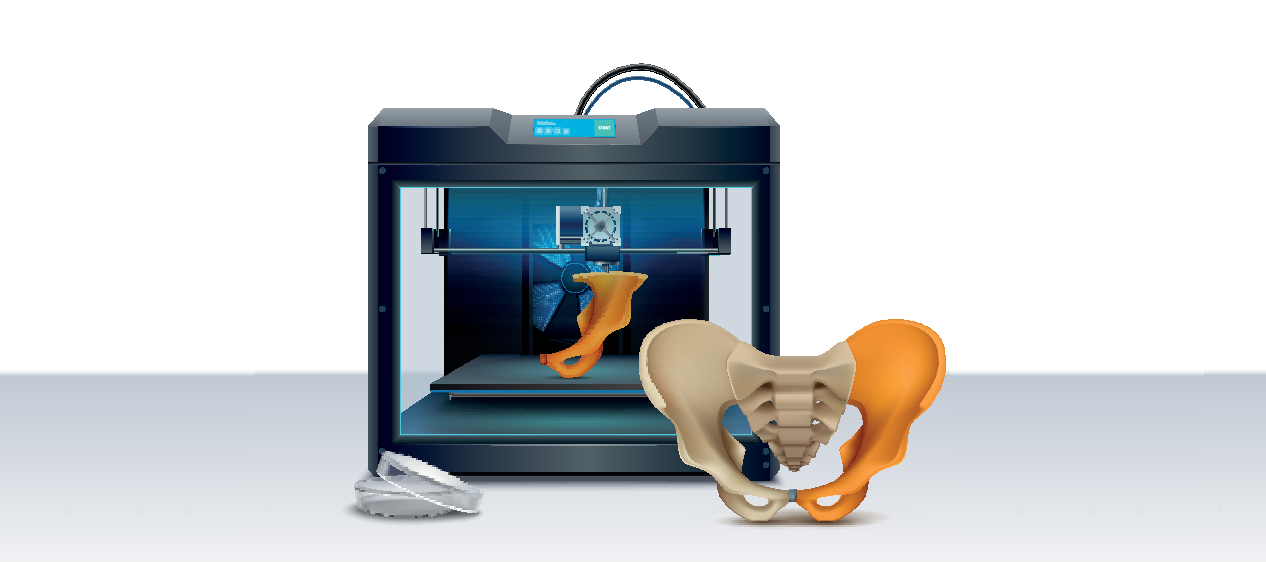

The integration of 3D printing into orthopaedic surgery marries cutting-edge technology with the precision demands of medical practice. This innovative approach not only elevates the standard of patient care but also redefines the possibilities within the field. By leveraging the capabilities of 3D printing to create anatomically precise models and custom-fit implants, surgeons are able to perform with greater accuracy. 3D printing has become a useful tool in preoperative planning, the customization of surgical instruments, and the optimization of patient outcomes, setting a new standard in orthopaedic surgery that emphasizes precision, customization, and innovation.

Customization and Precision

- 3D printing enables the creation of patient-specific anatomical models, derived from computed tomography (CT) or magnetic resonance imaging (MRI) scans.

- These models provide surgeons with detailed insights into a patient’s unique patho-anatomy, facilitating precise preoperative planning and optimization of surgical procedures.

- Customized implants, casts, orthoses, and prosthetics can be manufactured to match an individual’s anatomy, leading to improved fit, function, and patient outcomes.

Research Insights

- Recent studies have demonstrated the efficacy of modifying established orthopaedic implants, such as the locking compression plate (LCP), using 3D printing technology.

- Finite element modeling has shown that customizing LCPs can result in improved stress distribution and decreased peak stress levels compared to traditional implants.

- These findings suggest that 3D printing has the potential to enhance the performance and longevity of orthopaedic implants, driving further innovation in the field.

Preoperative Planning and Simulation

- 3D printing facilitates detailed surgical planning and simulation through the creation of patient-specific anatomical models.

- Surgeons can visualize surgical approaches, optimize procedures, and practice virtual osteotomies before entering the operating room.

- This preoperative preparation reduces surgical time, minimizes bleeding, anesthesia requirements, and the overall aggressiveness of surgery, leading to faster recovery times and improved patient satisfaction.

Patient-Specific Instruments and Surgical Guides

- 3D printing also enables the development of patient-specific instruments and surgical guides, further enhancing surgical precision and efficiency.

- These tailored tools empower surgeons to navigate complex anatomical challenges with confidence, resulting in more successful outcomes and fewer complications.

Challenges and Opportunities

- While 3D printing offers immense potential for customization and innovation, challenges such as the high cost of implants, lead time in manufacturing, and intraoperative flexibility must be addressed.

- Ongoing research into biomimetic materials and the development of integrated computer platforms are essential to further advance the clinical efficacy and accessibility of 3D printing in orthopaedics.

In orthopaedic surgery, 3D printing blends innovation with improved clinical outcomes. The technology’s ability to produce patient-specific implants and surgical instruments not only fine-tunes surgical precision but also significantly improves recovery processes. Despite facing challenges such as high costs and manufacturing delays, the ongoing development of new materials and technologies continues to push the boundaries of what is possible. As the field moves forward, the expanding capabilities of 3D printing promise to further revolutionize orthopaedic surgery, making personalized medical solutions more accessible and effective.

Sources:

3D printing and its applications in orthopaedic trauma: A technological marvel

3D Printing Applications in Orthopaedic Surgery: Clinical Experience and Opportunities

Use of Three-dimensional Printing in Orthopaedic Surgical Planning

Preoperative Planning Using 3D Printing Technology in Orthopedic Surgery

3D-printed patient-specific applications in orthopedics